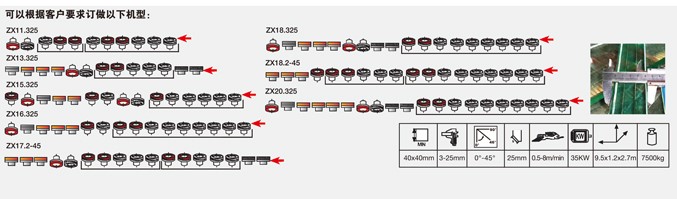

15 lub cev muaj zog automatical pob kabmob sib txawv lub kaum ntse ntse iav edging mitering tshuab

ZDM15.325

Ntau ntau 20-30 motors edging / mitering tshuab ua rau iav thiab siv lead ua

Tshuab Taw Qhia

1. Ntu seem 6 lub cev muaj zog (No.1-No.6) txheej txheem iav hauv qab ntug thiab sab pem hauv ntej miter ntug (0-60 degree), 2 lub cev muaj zog (No.7-No.8) rau rov qab seis zaum thiab 2 lub cev muaj zog ( No.9-No.10) rau pem hauv ntej tuaj txog. No.11.No.12 thiab No.13 lub cev muaj zog rau hauv qab ntug kev sib tsoo thiab qhov kawg polishing thaum No.1-No.6 motors rau pem hauv ntej miter ua. Kawg ob lub log yog rau pem hauv ntej thiab rov qab tuaj txog polishing. Tag nrho cov txheej txheem tiav rau ntawm ib qho kev mus ncig.

2. Lub tshuab no siv BEARING CONVEYOR SYSTEM. Nws haum rau cov iav me (40mmx40mm) thiab lub iav hnyav (4mx4m) kev coj ua. Sab saum toj kev teeb tsa qauv tuaj yeem ua rau cov xa khoom xa tawm kom ruaj khov rau cov iav me me 40mm qhov loj me.

3. Lub tshuab tau tiv thaiv iav tuab txheej txheem. Thaum tsis ncaj ncees lawm lub khob iav tau muab tso rau hauv lub tshuab. Lub tshuab yuav nres cia li. Qhov no tiv thaiv cov kabmob los ntawm kev zuaj.

4. Lub tshuab txais yuav PLC tswj thiab tus neeg teb xov tooj interface (Kov npo). Lub tshuab muaj 2 hom kev ua haujlwm, kev tuav thiab ua haujlwm tsis siv neeg ua haujlwm hom. Hauv hom tsis siv neeg, qhov tsis dhau ntawm glas tuaj yeem nkag los ntawm kov npo. Hauv phau ntawv hom, siv lub tshuab tuaj yeem ua haujlwm los ntawm kev hloov ntawm lub tshuab ua haujlwm.

5. Chaw thau khoom / thau khoom thauj khoom siv conveyor siv kev siv sijhawm. Nws tuaj yeem hloov qhov siab kom teeb tau ntau lub iav sib txawv.

6. Iav txhawb ncej siv Aluminium extrusion bar, nrog yas yob.

7. Lub conveyor npog yog ua nyob hauv stainless hlau.

8. Lub conveyor bearings yog lubricated los ntawm lubrication system, zoo tsim cov roj txoj kev tuaj yeem kom sab saum toj thiab hauv qab bearings kom tau txais roj roj tusyees.

9. Pem hauv ntej conveyor txav yog tsav tsheb. Nws tuaj yeem hloov kho los ntawm kab hluav taws xob khawm ntawm kev ua haujlwm haujlwm. Lub thickness yog tso rau ntawm qhov screen. Kuj tseem muaj cov neeg kho tshuab nyeem cov duab los qhia cov iav tuab.

10. Kev ua haujlwm ceev tuaj yeem hloov kho ntawm zaus zaus inverter.

11. Qhov kawg 3 lub log polishing tau hnov cov log polishing, uas muab tau zoo kawg nkaus rau ntawm lub khob. Lub taub dej dej yog sib cais.

12. Lub thawv nqa tawm rau lub kaum sib txawv hloov 6 lub log siv lub kaw lus tig. Qhov dej ntim dej tsis muaj kuab thiab kev tiv thaiv dej tiv thaiv nyob rau hauv lub conveyor nruab nrab ntawm txhua tus dej tank muab kev tiv thaiv zoo rau lub tshuab tiav.

13. Lub kaum sab xis tuaj yeem pom ntawm qhov screen.

14. Lub cev muaj zog siv cov tshuab ua muaj hluav taws xob siab ua los ntawm ABB, uas yog tshwj xeeb rau kev siv lub tshuab beveling.

15. Daim iav txheej txheem saum npoo yog qhov ci heev thiab du, nce mus rau lub qub iav nto. Lub tshuab no tseem tshwj xeeb los ntawm kev ua ntau yam thiab ua haujlwm yooj yim.

Kev tsis

|

Lub kaum ntse ntse hloov ntau yam |

0-45 degree. |

|

Log kom muaj nuj nqis rau miter |

6 |

|

Ua haujlwm Ceev: |

0.4m-3.8m / min |

|

Sib tsoo qhov tob: |

3 hli |

|

Max. miter dav: |

30 hli |

|

Iav thickness: |

3mm-25mm |

|

Min. iav Qhov Coob: |

40mmX40mm |

|

Tag Nrho Cov Zog: |

20kw |

|

Zuag qhia tag nrho qhov ntev: |

8.6mx1.2mx3.5m |

|

Spindles: |

15 lub taub hau. |